At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.

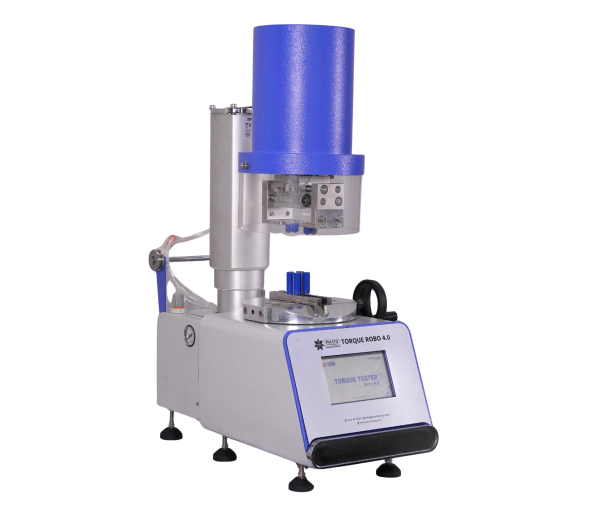

The Torque Tester Robo 4.0 is a high-precision, automated torque testing system designed for industrial and laboratory use. Combining advanced sensors and smart automation, it delivers accurate, reliable, and repeatable torque measurements, ensuring optimal performance, quality control, and safety across manufacturing, research, and calibration applications.

Read More

The Secure Seal Tester is a reliable testing instrument designed to measure seal integrity in PET and plastic containers. This essential quality test ensures leak-proof bottle caps, particularly crucial in carbonated beverage production facilities.

Read More

The Top Load Tester is an advanced, fully automatic motorized device designed to measure compressive buckling load in a digital format. Its digital display is not only visually appealing but also sophisticated, ensuring easy readability. Key features include an Auto Tare (ZERO) set facility and a Peak Hold arrangement.

Read More

The Presto Tensile Testing Machine operates on the Constant Rate of Traverse (CRT) principle. In this test, the sample is clamped between two jaws, with the upper jaw remaining stationary while the lower jaw moves at a fixed speed controlled by a motor.

Read More

The Digital Eco Vacuum Leak Tester is an affordable and efficient solution designed to enhance quality control in packaging applications. Engineered with exceptional precision, this laboratory testing equipment accurately detects leaks in various packaging materials.

Read More

Hello, Uganda! Ready to take it to the next level when it comes to testing? We at Presto International believe that with bottles, it is not only what is inside, but also if the container is one that will last and withstand pressure. You are, therefore, either a manufacturer or supplier for whom our Bottle Test Systems in Uganda are designed to ensure that your products meet standards and your customers love them.

Presto Instruments is a leading manufacturer and supplier of Bottle Testing Solutions in Uganda For the best price, contact us for a quote or call now!

Because over 11,436 customers across the globe have put their faith in us and we have surpassed their expectations. And, because we ensure...

We are National Quality Award winners from the Government of India. All our products are unmatched in quality and design.

All our Products are manufactured in our 2 state of the art factories. They are standardised using CNC machines to provide long term cost benifits to customers.

40+ years of experience in providing testing solutions to the world.

180+ Team members to provide best services PAN India and globally.