Model : PSST-0113

A Secure Seal Tester is a laboratory test equipment employed to assess the seal integrity and leakage resistance of plastic or glass containers such as bottles, jars, etc. It tests whether the cap or closure of the container can resist internal pressure without leaking, making the product safe when it is stored or transported.

The test is done by pressurizing the sealed container using air or water and checking for pressure loss or visible leaks. This tool is commonly applied within the packaging, beverage, pharmaceutical, and food manufacturing industries to ensure packaging quality, avoid contamination, and meet industry standards for safe sealing performance.

A Secure Seal Tester is a quality control tool employed to measure the sealing strength and leak tightness of packaging like PET bottles, jars, and cans. It guarantees that the package is well sealed to avoid leakage, contamination, or carbonation loss. This testing equipment finds widespread application in the beverage, food, and pharmaceutical industries to ensure packaging performance.

The principle of operation of a Secure Seal Tester relies on the pressure decay or pressurization technique. A container in sealed condition is exposed to controlled internal air or gas pressure, and any pressure loss or visible leakage confirms a weak or faulty seal.

The Secure Seal Tester operates by subjecting the sealed container to controlled air or gas pressure within a sealed vessel to test its seal strength. The vessel is placed in water or a sealed chamber, and pressure is applied gradually up to a set point. If there is the presence of air bubbles or a pressure drop, it reflects a leakage or a weak seal. This process assists in detecting faulty closures so that bottles or jars are able to ensure product freshness, avoid contamination, and resist actual conditions of handling and shipping.

Here are the benefits of a secure seal tester explained in detail:

Provides Leak-Proof Packaging

The Secure Seal Tester assists in the detection of any leakage or poor sealing in containers to ensure that products are safe and free from contamination. Through the testing of seal integrity, manufacturers are able to avoid product wastage, leakage during transportation, and customer dissatisfaction, thus achieving regular packaging quality and brand reputation.

Improves Product Shelf Life

By providing an airtight and secure closure, the tester precludes air, moisture, or contaminants from entering. This preserves the freshness, carbonation, and quality of drinks or other perishable products, ultimately leading to the extension of product shelf life and allowing consumers to receive products in the best possible condition.

Facilitates Quality Control and Compliance

The Secure Seal Tester enables companies to meet industry packaging integrity standards. Constant testing guarantees every batch is compliant with regulatory demands and internal quality specifications, preventing recalls or rejections. It enhances quality assurance processes and enhances consumer confidence in product reliability.

Reduces Production Losses

Early detection of seal defects during the manufacturing process reduces wastage of material and saves costs associated with product returns or leakage cases. Through the guarantee of only sealed containers being available at the market, the tester enhances general production efficiency and operational profitability for manufacturers.

Here are the applications of the secure seal tester explained in detail:

Soft Drink Industry

In the soft drink industry, the Secure Seal Tester makes sure bottles of carbonated beverages, juices, or water are tightly sealed to avoid loss of gas or leakage. It checks for cap integrity and closure performance, keeping the product fresh, carbonated, and ensuring consumer satisfaction during storage and transportation.

Food Packaging Industry

The tester is applied to test seal integrity in sauce jars, cans, and containers storing oils or processed foods. It avoids contamination, spoilage, and leakage by ensuring airtight seals, ensuring that manufacturers keep hygiene levels high, and increasing the shelf life of packaged foods is increased.

Pharmaceutical Industry

In the pharmaceuticals industry, the Secure Seal Tester prevents containers of medicine, vials, and bottles from being improperly sealed and exposed to moisture or air entry. The test is important for ensuring drug stability, potency, and sterility so that drugs are safe and effective up to the point of the end user.

Cosmetic and Personal Care Industry

The tester is applied to test the bottle, tube, and jar sealing of creams, lotions, and other cosmetics. It avoids leakage or contamination during transportation and handling, ensuring product quality, appearance, and consumer confidence in the reliability of the brand's packages.

Presto Instruments Secure Seal Tester is precision-engineered and reliable to provide precise leak detection in bottles and containers. Made from advanced technology and rugged materials, it provides consistent results for quality testing.

Easy to use in design, it provides a long service life with its rugged construction. Presto's tester is international testing standard-compliant, and hence it is particularly suited for applications such as beverages, food, and pharmaceuticals that demand reliable packaging integrity testing for product performance and safety.

Presto Instruments is a leading manufacturer and supplier of Secure Seal Tester NXG For the best price, contact us for a quote or call now!

The Secure Seal Tester NXG is a laboratory/quality-control instrument designed to measure the seal integrity of bottles, jars or other sealed containers (glass or plastic) — in particular containers used for carbonated beverages, soft drinks, juices and similar products.

Here are some of the principal features/specs for the NXG model:

Display: HMI touchscreen interface (in the NXG “Next Generation” variant) for easier user operation.

Test/Equipment Range: Up to ~220 psi equipment range / ~175 psi test range (in many models).

Accuracy: Approximately ±2% of full range.

Resolution/Least count: 0.1 psi (for digital gauge) in some models.

Power: Typical 220 V, single phase, 50 Hz.

Pressure units: Changeable (psi, bar, kg/cm², lb/in²) in some versions.

Inner diameter (sample chamber): ~200 mm in some versions.

Materials / construction: Anodized aluminium, stainless steel, high‐tensile plexiglass / safety shield.

Data output / management: USB option for data export, ability to record product ID, test pressure, time, graphical output.

Automatic sample testing / pressure release mechanism (in NXG).

The Secure Seal Tester NXG is suitable for:

Carbonated‐beverage bottles (PET, glass) using roll-on crowns, twist crowns, plastic caps.

Non‐carbonated beverage bottles, juice bottles, water bottles.

Pharmaceutical bottles or containers with sealed closures (though specifications may vary).

More broadly, any sealed container where you need to assess leak or seal integrity (within the machine’s size/pressure limits)

While exact operational details may vary by model, typically:

The container to be tested is sealed and placed in the test chamber of the instrument.

A defined pressure is applied (or vacuum) to the container (or to the chamber around it) to test whether the seal holds.

The instrument monitors pressure (or time/pressure drop) and may provide a pressure-vs-time graph. In the NXG version this graphing feature is explicitly noted.

If a leak or weak seal exists, pressure drops (or gas escapes) and the instrument detects that deviation, indicating failure of seal integrity.

Use on a stable 220 V single‐phase supply (in standard version) at 50 Hz.

Place sample container (bottle, jar) within the machine’s capacity (e.g., internal diameter ~200 mm) and ensure proper sealing/clamping for test.

Set test pressure, time (preset up to e.g., 999 seconds in some models) and units appropriately for your container/closure type.

After test start, monitor status; export data via USB if needed.

Ensure operator safety: many machines include plexiglass safety shields, etc.

The aerated & carbonated drinks have taken over the market by storm since their introduction. These drinks are supplied all across the globe and our widely consumed by customers. The production process of these drinks is very crucial as these drinks should contain a particular amount of carbonation to achieve consumer satisfaction levels and enhance the customer experience.

Read More

The Digital Eco Vacuum Leak Tester is an affordable and efficient solution designed to enhance quality control in packaging applications. Engineered with exceptional precision, this laboratory testing equipment accurately detects leaks in various packaging materials.

Read More

The Vacuum Leak Tester for PET Bottles is a testing instrument designed to check the seal integrity and leak resistance of all types of PET bottles. This is perfect for use in food, medicine, beverage industries, and others where PET bottles are used for product transportation or storage.

Read More

A Bottle Burst Tester – Digital is a precision instrument used to measure the pressure resistance and overall strength of PET and plastic bottles. By gradually applying controlled internal pressure, it accurately determines the burst point, helping manufacturers ensure quality, safety, and compliance with industry standards.

Read More

The touchscreen model introduces a modern approach to testing, offering smoother operation and significantly improved data visibility. Unlike traditional knob-based or analog testers, this system allows for quick adjustments, immediate result tracking, and digital recordkeeping—saving time and boosting production efficiency.

Read More

A Vacuum Tester for Plastic Containers is a precision device used to check the sealing strength, leak resistance, and durability of plastic packaging. By creating controlled vacuum conditions, it quickly identifies weak seals, air leaks, and structural defects that could compromise product safety. Ideal for food, pharmaceutical, cosmetic, and industrial packaging, this tester ensures reliable quality control, reduces waste, and helps manufacturers meet strict industry standards.

Read More

A Bottle Cap Pull-Out Tester is a precision device used to measure the force required to pull a cap off a bottle. It helps manufacturers verify sealing strength, ensure closure integrity, and maintain consistent packaging quality. By applying a controlled tensile force to the cap, the tester provides accurate pull-out force readings, making it essential for quality control in beverage, pharmaceutical, cosmetic, and chemical packaging industries.

Read More

The Base clearance membrane is a lab testing instrument created after thorough research & development for the manufacturers of PET preforms & bottle industry. This testing instrument is dedicated for analyzing the depth of the containers as well as bottles. It is extremely important to determine the accurate depth of the containers & bottles to calculate the right volume of the same, and thus fill it with the respected amount.

Read More

The Presto Vacuum Leak Detection System is now offered in the Prima series. Featuring an HMI touchscreen display and fully automatic controls, this system guarantees precise and repeatable results, along with comprehensive data acquisition for various tests. The vacuum tank is specifically engineered to perform leak integrity testing on large-sized packages using any testing medium.

Read More

Introducing the Presto Vacuum Leak Detection System now featured in the Prima series. Equipped with an intuitive HMI Touch Screen Display and fully automated controls, this system ensures precision with consistency while facilitating data acquisition for a variety of tests.

Read More

The Top Load Tester is an advanced, fully automatic motorized device designed to measure compressive buckling load in a digital format. Its digital display is not only visually appealing but also sophisticated, ensuring easy readability. Key features include an Auto Tare (ZERO) set facility and a Peak Hold arrangement.

Read More

The Top Load Tester - Digital Cum Computerized is a state-of-the-art, fully automatic motorized top load tester. It measures compressive buckling load and displays the results digitally. The high-end digital display is sophisticated and includes an Auto Tare (ZERO) set feature and a Peak Hold function. For secure gripping with no slippage, the test sample is positioned between inverted concave jaws.

Read More

Introducing the new generation Top Load Tester - Prima Series, designed specifically for PET bottles and jars. This fully automatic motorized device applies compressive buckling load to products with precision. The instrument features a Human Machine Interface (HMI) based Touchscreen display, providing easy access to compressive buckling load readings.

Read More

The Top Load Tester Digital for Jars is a precision instrument designed to measure the vertical compression strength of PET, HDPE, and glass jars. It uses advanced digital load cells and a motorized compression system to accurately determine how much top pressure a jar can withstand before deforming or collapsing. Ideal for quality control and R&D, this tester ensures packaging durability during capping, stacking, handling, and transportation.

Read More

The Secure Seal Tester – Next Generation is a cutting-edge device designed to ensure the integrity and safety of sealed products. Combining precision technology with user-friendly operation, it quickly detects weak or faulty seals, preventing leaks, contamination, and product loss. Ideal for food, pharmaceutical, cosmetic, and consumer goods industries.

Read More

The Seal Integrity Tester for pouches plays a critical role in ensuring the integrity of pouch packaging used for various products. Detecting any potential leakage in the seals is essential to prevent product spillage and maintain packaging integrity.

Read More

The PDW 30 series models feature two free piston assemblies, allowing for the application of both low pressure range with small steps and high pressure range with larger steps. This integration into a single instrument results in significant cost savings.

Read More

The preform perpendicularity tester is one of the high quality lab testing instrument that helps the manufacturers in testing the perpendicularity of the preforms. The shape, size, and other general qualities of a preform have a significant influence on the perpendicularity.

Read More

Ensure every bottle stands perfectly upright with the Bottle Perpendicularity Tester. Designed for beverages, pharmaceuticals, cosmetics, and food industries, this precision instrument measures bottle tilt accurately and efficiently. It helps maintain quality control, reduces waste, improves shelf appeal, and ensures compliance with industry standards.

Read More

The G V Shaker is a durable, leak-proof bottle designed for effortless mixing of protein shakes, smoothies, and supplements. Made from high-quality, food-grade materials, it ensures smooth, clump-free drinks on the go, making it perfect for workouts, travel, or daily use.

Read More

Presto’s Hot Wire Bottle Cutter is a widely utilized instrument in the PET bottle industry, crucial for packaging products such as carbonated drinks, food items, and chemicals.

Read More

The Hot Wire Bottle Cutter - NXG is a next-generation tester designed for precise section weight analysis of PET bottles and containers. It features digital heat monitoring for accurate control.

Read More

The Impact Tester for Glass Bottles is a precision device designed to measure the strength and durability of glass bottles against sudden impact or shock. It delivers controlled, repeatable force to identify weak points and ensure bottles can withstand handling, transportation, and filling processes. Ideal for beverage, pharmaceutical, food, and cosmetic industries, this tester helps manufacturers improve packaging quality, reduce breakage, and meet international safety standards.

Read More

PI Tapes are precision measuring tools designed for accurate diameter measurement of cylindrical objects such as pipes, rods, and shafts. Easy to use and highly reliable, they provide direct readings with minimal error, making them ideal for engineering, manufacturing, and quality control applications.

Read More

Wall Thickness Gauge is a precision, non-destructive measuring tool designed to quickly and accurately determine the thickness of metals, plastics, glass, and other solid materials. Using advanced ultrasonic technology, it helps inspectors detect corrosion, wear, and structural weaknesses without damaging the surface.

Read More

Preform & Bottle ‘NECK’ Cutter is a precision tool designed to cleanly remove the neck portion of PET preforms and plastic bottles with accuracy and ease. Engineered for manufacturing, recycling, and quality-control applications, it delivers smooth, consistent cuts without damaging the bottle body.

Read More

The Preform Defect Chart is an essential testing instrument utilized across industries and laboratories for the visual assessment and evaluation of defects in PET preforms.

Read More

The Torque Tester Motorised: Pluto Series is a precision motorized device designed for accurate and consistent torque measurement. Ideal for quality control and research, it features automated testing, real-time digital readings, and adjustable speed control for a wide range of applications—from bottle caps and closures to mechanical and electronic components. Durable, user-friendly, and highly efficient, the Pluto Series ensures reliable results every time.

Read More

The Cap Pull-Out Tester is a precision quality-control instrument designed to measure the force required to remove caps, lids, or closures from containers. Ideal for packaging, food & beverage, pharmaceutical, and cosmetic industries, it ensures consistent seal strength, prevents leakage, and verifies compliance with industry standards.

Read More

The Presto Tensile Testing Machine operates on the Constant Rate of Traverse (CRT) principle. In this test, the sample is clamped between two jaws, with the upper jaw remaining stationary while the lower jaw moves at a fixed speed controlled by a motor.

Read More

Introducing the Presto Torque Tester – HMI Touch Screen, a cutting-edge, fully automatic torque testing solution. This next-generation tester provides torque readings in digital format, offering unparalleled accuracy and convenience.

Read More

The Torque Tester – Prima Hand Operated is a precision mechanical tool designed to measure torque accurately on bolts, screws, and fasteners. Ergonomically built and fully portable, it delivers reliable readings without electricity, making it perfect for quality control, maintenance, and industrial applications. Durable, easy to use, and highly accurate.

Read More

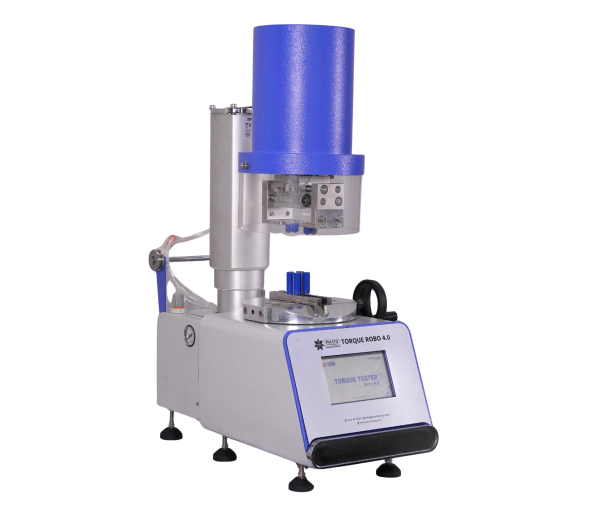

The Torque Tester Robo 4.0 is a high-precision, automated torque testing system designed for industrial and laboratory use. Combining advanced sensors and smart automation, it delivers accurate, reliable, and repeatable torque measurements, ensuring optimal performance, quality control, and safety across manufacturing, research, and calibration applications.

Read More

Moisture Analyzer-95 is a high-precision device for quickly determining moisture content in powders, granules, solids, and pastes. With fast, accurate results and an easy-to-use interface, it’s ideal for laboratories, quality control, and industrial applications across food, pharmaceuticals, chemicals, and agriculture.

Read More

A Digital Profile Projector is an advanced optical measuring instrument used to inspect and measure small mechanical parts with high precision. It projects the enlarged profile of an object onto a screen and provides accurate digital measurements of dimensions, angles, and contours. Widely used in manufacturing, automotive, aerospace, and tool-making industries, it ensures quality control and precise component analysis.

Read More

Autoclaves and sterilizers are important machinery that are employed to kill living organisms that are harmful in the form of high-pressure steam. They offer a dependable sterilization method of medical equipment, lab materials, and other heat-resistant products that are chemical-free.

Read More

Laminar Air Flow Bench is a valuable equipment to all people in the practice who need to have a sterile and controlled working atmosphere. This bench is designed with the high cleanliness in mind, where ambient air is drawn in and run through a pre-filter and then into high-performance HEPA or ULPA filter.

Read More

The Bench Top pH/mV Meter is a high-quality laboratory device that is used to provide precise pH and millivolt readings in scientific, industrial and educational needs. It provides a stable performance with advanced calibration possibilities and easy to use interface which guarantees high-quality results during routine testing and meaningful analysis.

Read More

BOD Incubator - Prima Series is an accurate Biological Oxygen Demand (BOD) incubator and low-temperature incubator with a high degree of control. It has an advanced microprocessor control, uniform cooling and low-energy consumption operation, which require a dependable performance in environmental, microbiology, and research applications.

Read More

At Presto, we take pride in being Global manufacturers of Laboratory Testing Instruments for different industries.